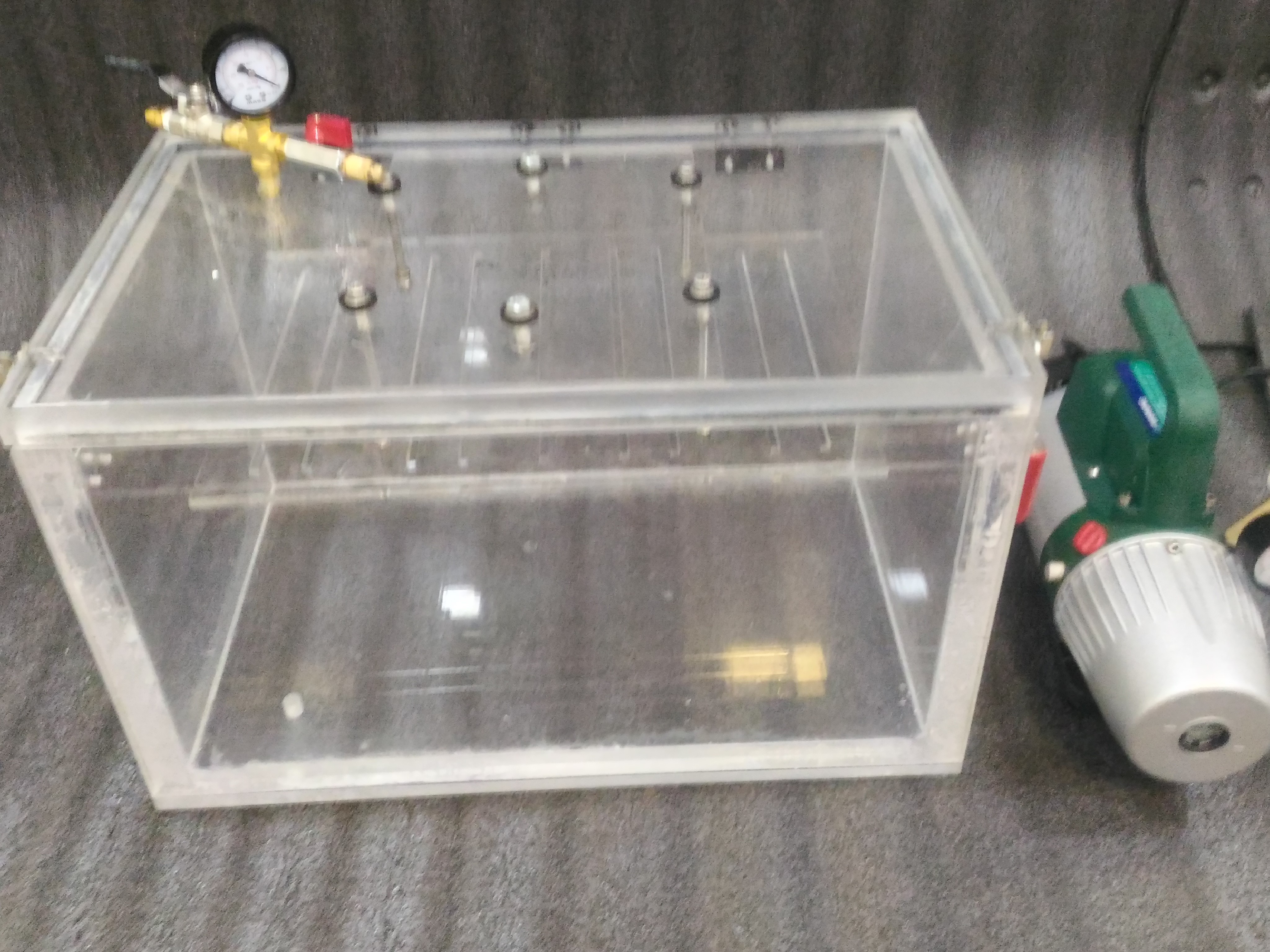

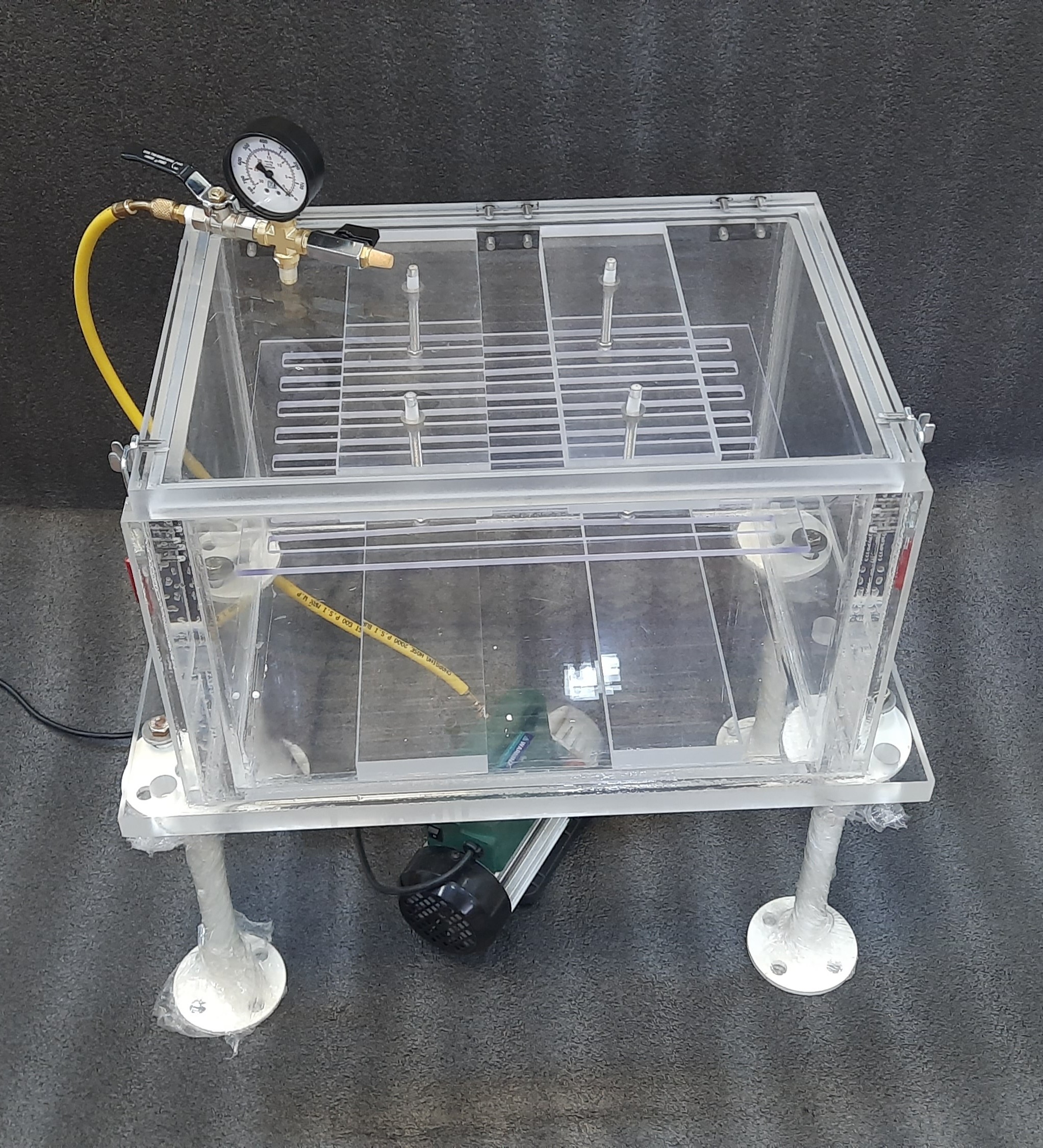

Vacuum Leak detector machine manufactured by Burhani Hardware used for Package Leak Detector and Seal Tester in application such as Package Manufacturers, Sea packaged food, meat packaged food , cheese, Pet Food, Medical pouches, Pharmaceutical pouch, cosmetic, Dairy products, Cereal and Grains, Bakery Products, snack food, coffee and tea, confectionary and other related products.

What is vacuum leak

detector

Pack-Vac

Leak Detectors Leak Testers

Pack-Vac

Leak Detectors from Burhani Hardware

And Fittings for Quality Control

Burhani Pack-Vac

Leak Detectors assist you guarantee to your customers that your packaging

system is dependable once it leaves your facility.

Sealing

time, packing material compatibility, seal reliability in high altitude

trucking and airfreight are some of the production variables that has to be

taken into account since the manufacturing possibilities are countless.

Leak Test

Video

Burhani pack-vac

leak detectors allow you to set up reliable package line quickly without

efforts. This is a systematic package testing system. This results in accurate

adjustment of machinery and less downtime. Continues usage of Burhani Pack-Vac

leak Detectors can detect sealing problems before they snowball. By this way,

the production yield is improved. Hence Burhani Pack-Vac

leak detectors can diagnose the defects before reaching customer. A Touch

Screen PLC can be added to the system to stimulate High altitude and vacuum

levels for ideal situations.

Operation

Burhani Pack-vac

leak detectors can perform vacuum test in less than 10 to 30 seconds. The Unit

is partly filled with water for vacuum leakage test. The burst test can be done

dry. Drop your sealed package inside the chamber, close the lid and engage the

vacuum lever. Watch for bubbles in case of leakage.

The Burhani Pack-Vac

Leak Detectors is used to perform a variety of ASTM test methods for detecting

leaks and seal integrity.

ASTM

D6653 Standard Test Methods for Determining the Effects of High Altitude on

Packaging Systems by Vacuum Method

ASTM

D3078 Standard Test Method for Determination of Leaks in Flexible Packaging by

Bubble Emission

ASTM

D4991 Standard Test Method for Leakage Testing of Empty Rigid Containers by

Vacuum Method

ASTM

D4169 Standard Practice for Performance Testing of Shipping Containers and

Systems

ASTM

F2096 Standard Test Method for Detecting Gross Leaks in Packaging by Internal

Pressurization (Bubble Test) – Using our optional adapter

ASTM

D5094 Standard Test Methods for Gross Leakage of Liquids from Containers with

Threaded or Lug-Style Closures

Choosing

the Right Burhani Pack-Vac

Leak Detector

Now that

you know you need one of our Pack-Vac Leak Detectors, here’s how to find the

right one for your application.

Connection

Requirements

we

recommend the Electric Vacuum Pump. Our electric model comes equipped with a

quiet and durable vacuum pump, 230/115 VAC standard(unless otherwise

specified).

Size

Burhani Hardware

can craft custom size vacuum chambers. Also Burhani Pack-Vac

Leak Detectors are available in eight production models. You can choose from

any one or custom make according to your requirements. We can also help our

customers to select size based on their packages. with our innovative machining

centres we offer high quality and affordable prices for burhani pack vac

leak detector..

Consistent shelf-life for our packaged products has allowed us to extend our market reach.

ReplyDeleteWith the vacuum leak detector as a critical part of our QC program, we meet and exceed those expectations

ReplyDeleteVacuum degassing chamber manufactured by BHFTECH Burhani Engineering Technology is a vacuum system comprising of Vacuum chamber and vacuum pump that pulls 29 inches of mercury is used to remove the air from high viscosity materials like epoxy resin, Liquid silicone rubber, liquid plastic and Polyurethane rubber to make bubble free casting. BHFTECH is the only exporter and manufacturer of resin vacuum degasser chamber in India for degassing silicone.

ReplyDeleteanufactured by Burhani Engineering Technology is a vacuum system comprising of Vacuum chamber and vacuum pump that pulls 29 inches of mercury is used to remove the air from high viscosity materials like epoxy resin, Liquid silicone rubber, liquid plastic and Polyurethane rubber to make bubble free casting. Burhani Engineering Technology is the only exporter and manufacturer of resin vacuum degasser chamber in India for degassing silicone.

Delete