—Vacuum

leak detector is a Simple, Affordable, reliable and repeatable leak detection

equipment. Vacuum leak machine can be used for Continual testing on the

production line. The Machine is capable to detect sealing problems before they

snowball. A quality control system that incorporates the Burhani Leak

Detector will allow you to quickly and reliably setup packaging lines. The

Packing Materials can be tested for seal integrity during package development.

Altitude simulation also assures package integrity during trucking and

airfreight. Above all, the Pack-Vac Leak Detector will catch defects before

they get to your customers.

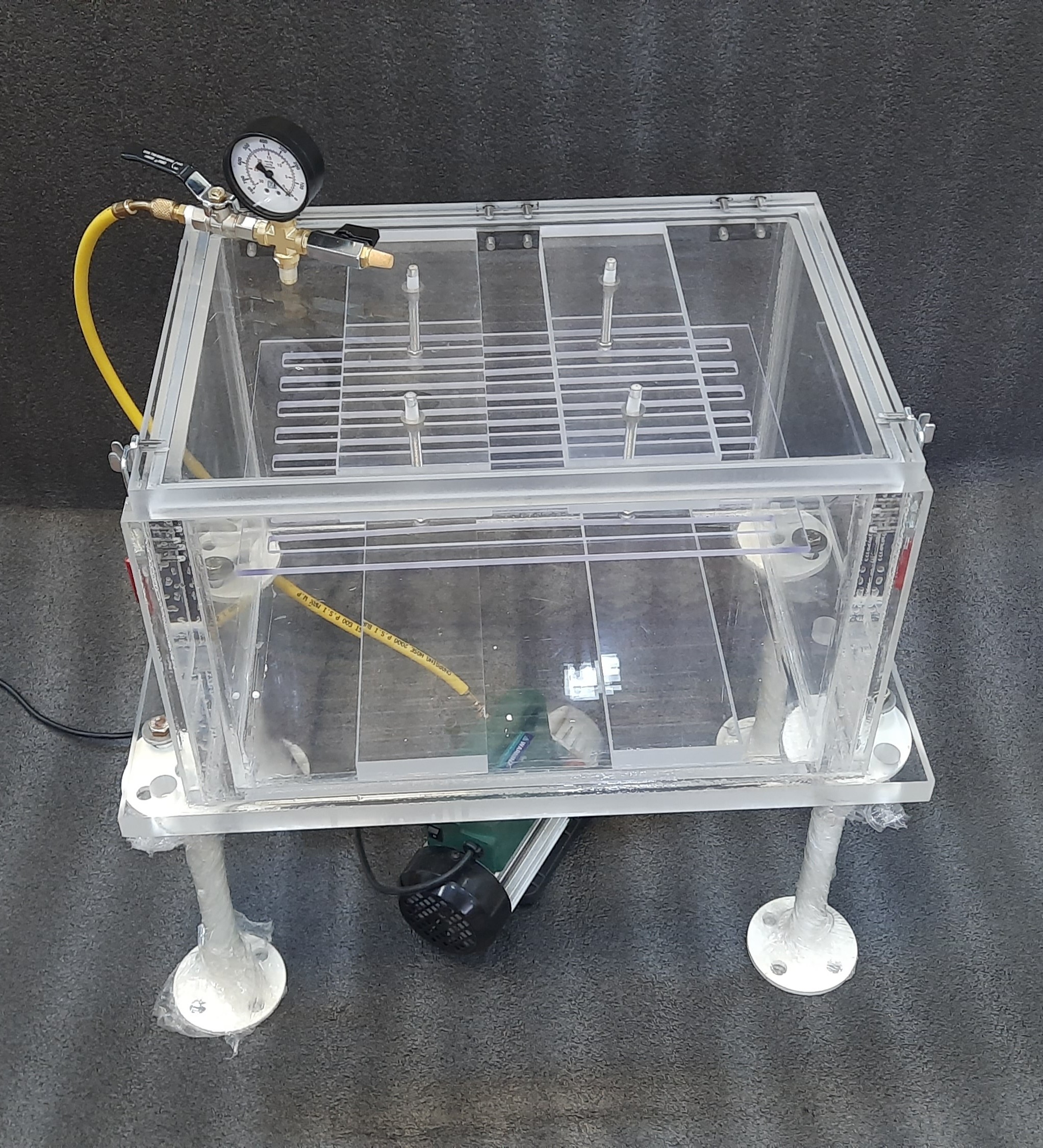

The Burhani Vacuum Chamber clear tank provides 360° viewing. A stream of

bubbles will rise from a leak.

—

Continuous quality control

—

Packaging machine setup

—

Material testing

—

Altitude simulation

Operation

The Burhani vacuum

Leak Detector allows the user to perform a vacuum leak test in less than 30

seconds. Place your sealed package, close the lid and engage the vacuum device.

Now watch for bubbles. If Bubbles Raises out then it confirms for mini holes or

leaks . As easy as 1-2-3.

Ongoing

quality control is our top priority; our customers expect and deserve good

packaging. With the vacuum leak detector as a critical part of our QC program,

we meet and exceed those expectations.”

We use

the Burhani Vacuum

Leak Detector Chamber for ongoing product development and field trials of our

packaging systems. Its reliable and simple operation allows us to quickly

resolve sealing issues before they affect our customers.”

Consistent

shelf-life for our packaged products has allowed us to extend our market reach.

The vacuum leak detector helps us guarantee the freshness of our delivered

goods..

visit at: https://bhfvacuum.com/

Consistent shelf-life for our packaged products has allowed us to extend our market reach.

ReplyDeleteWith the vacuum leak detector as a critical part of our QC program, we meet and exceed those expectationshttps://bhfvacuum.com/bubble-emmission-leak-test-chamber.html

ReplyDeleteVacuum degassing chamber manufactured by BHFTECH Burhani Engineering Technology is a vacuum system comprising of Vacuum chamber and vacuum pump that pulls 29 inches of mercury is used to remove the air from high viscosity materials like epoxy resin, Liquid silicone rubber, liquid plastic and Polyurethane rubber to make bubble free casting. BHFTECH is the only exporter and manufacturer of resin vacuum degasser chamber in India for degassing silicone.

ReplyDeleteanufactured by Burhani Engineering Technology is a vacuum system comprising of Vacuum chamber and vacuum pump that pulls 29 inches of mercury is used to remove the air from high viscosity materials like epoxy resin, Liquid silicone rubber, liquid plastic and Polyurethane rubber to make bubble free casting. Burhani Engineering Technology is the only exporter and manufacturer of resin vacuum degasser chamber in India for degassing silicone.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteThe Vacuum leak tester is an essential tool for ensuring the integrity of packaging. By identifying leaks quickly and accurately, it helps maintain product quality and safety. This device is invaluable for manufacturers aiming to deliver reliable, well-preserved goods to consumers.

ReplyDelete